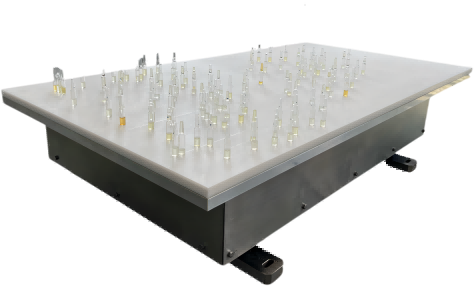

Spring untangler

GOODBOWL supply you a complete range of product and components: high-performance drives, belts and vibratory pots, hoists, spring separators and controls, as well as high-quality and high-performance accessories. In addition to standard components, we also manufacture and supply system-specific components, such as tilt feeders, to meet special performance requirements. This also includes designs for special industries, such as the pharmaceutical and food industries. Optimal service, fast delivery, and high availability are always our top priorities. Most of our products are CE certified.

The drives and components for feeding systems are available for your regular configuration options, we can also supply you the flexible design and manufacturing to meet your specific needs. Standard inventory management allows you to place spare parts orders anytime and anywhere, and achieve rapid replacement.

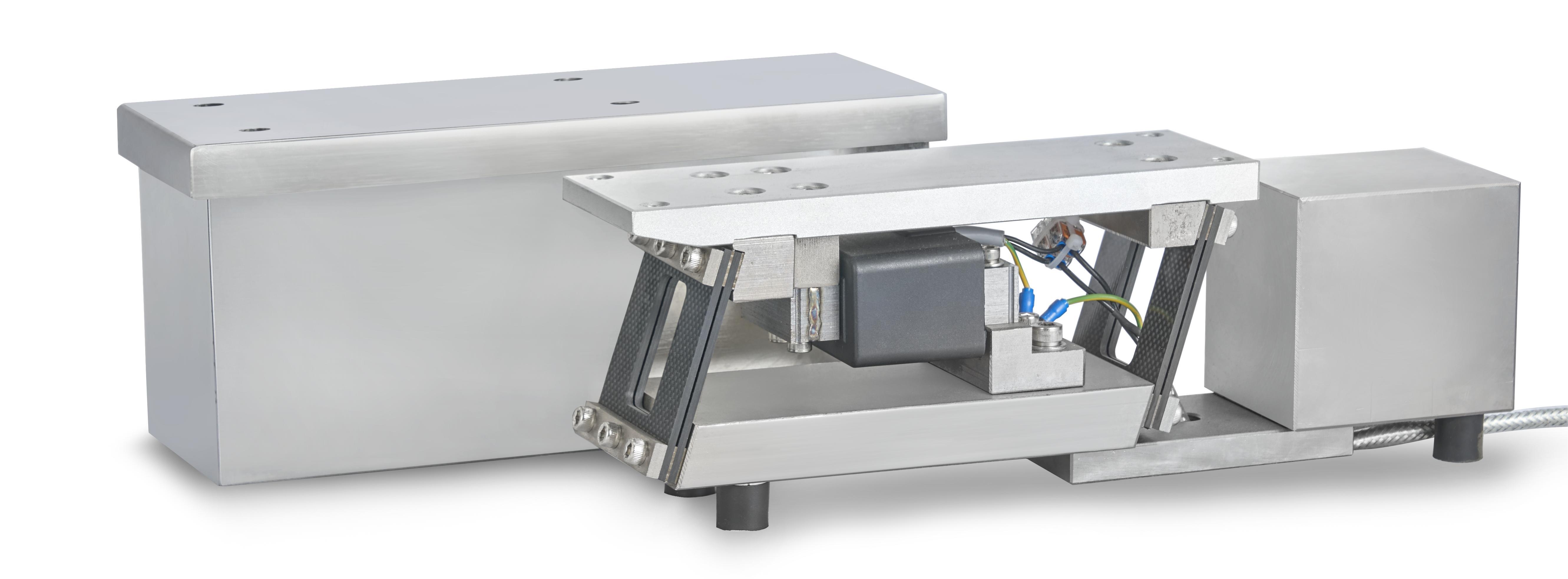

Rotary drives and Linear drives

Rotary drives

Our standard round drivers can cover most of the specifications from 150-800mm

we have 10 standard specifications, and we also support non-standard designs for you

Configuration Options:

Half shell (simple structure, not waterproof)

Full shell (easier to clear, splash resistant)

Isolator version (hermetically sealed, washable and VHP sterilizable)

Manual bolt locking

Vacuum locking

Linear drives

Providing driving force forlinear orbit to achieve extension of the conveying distance of the vibration cooker.

Features:

According to GMP guideline,use SUS316L or SUs3C 04 stainless steel material for cladding.

High reliability-high quality electromagnetic module is adopted with little heat and constant power.

Low noiseusing composite spring module with minimal mechanical noise.

High stability-The accurate weight ratio brings a steady and high-speed vibration output,

which is fast and small beating.

Easy to maintain optimized structure convenient for repair,

modular components that lower your inventory of spare parts.

Multiple fastening modes optional.(refer to sorting bowl fastening mode,support upgrade modification).

Usingin isolators optional configuration,fully sealed construction,washable,VHP in-line sterilization supported.

Fill specifications support track length 80-4000 mm.

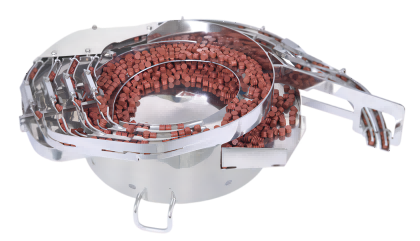

Bowl feeder

Bowl

It can be used for pre-sorting, sorting, conveying and supplying parts.

We offer cylindrical, conical and stepped pots in stainless steel, as well as bowl feeders made of synthetic materials.

Type:

Conical type [simple structure, high conveying efficiency. Diameter 150-800mm can be customized]

Cylindrical type [large loading capacity, easy to achieve multi-channel output, diameter 150-1000 can be customized]

Ladder type [high-speed conveying of materials with simple appearance,

moderate loading capacity, diameter 200-1000 can be customized)

Switch the installation type:

External bolt tightening (manual operation, low cost)

Electric quick tightening [electric motor automatic, easy to operate]

Vacuum fastening (more convenient installation, no mechanical friction in the fastening process,

more suitable for aseptic environment)

Surface treatment:

Mechanical polishing

Electrochemical polishing

Ceramic sand spraying

Other special surface requirements

File support:

Material Certificates

Proof of welding

Surface roughness measurement

Ferrite content measurement

Test documentation

Consumables Buying Guide

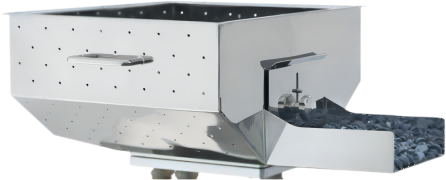

Vibratory hopper

Vibratory hopper

Bulk materials are put into the storage silo, driven by the linear vibrator, the materials are evenly conveyed to the sorting and feeding unit for precise conveying,

and we can achieve full-scale customization for customers to meet all their needs.

Peculiarity:

Effectively extend the interval between manual feeding.

Cooperate with sensors to achieve millimeter-level accurate level control.

It has a better separation effect for materials that are easy to stick and insert.

All parts in contact with the material can be disassembled and sterilized.

Intermittent vibration to reduce material wear.

The adaptability of materials is stronger.

Installation:

Screw fastening

Vacuum fastening

Manual quick lock cam fastening

Surface treatment:

All welding positions, full welding on both sides, polished to mirror surface

Ceramic sand spraying is optional

Electropolishing is optional

Other specified coatings can be selected

Incline feeder

Incline feeder

The bulk material is put into the hoist silo, and the hoist will convey the appropriate amount of material to the sorting and feeding unit for accurate conveying.

In order to meet the complex requirements of our customers, different volumes and conveying distances can be flexibly customized

depending on the conveying object and technical objectives.

Features:

The height of the discharge can be designed according to different working conditions.

While meeting your needs, we can achieve a smaller footprint.

The volume of the silo can be customized according to the requirements.

Very low material wear ·

The speed is adjustable and the level is precisely controlled.

The surface in contact with the material is made of sanitary stainless steel, which is easy to clean.

Standard bin volume (Litres)--40/50/60/100/150/200/500/1000

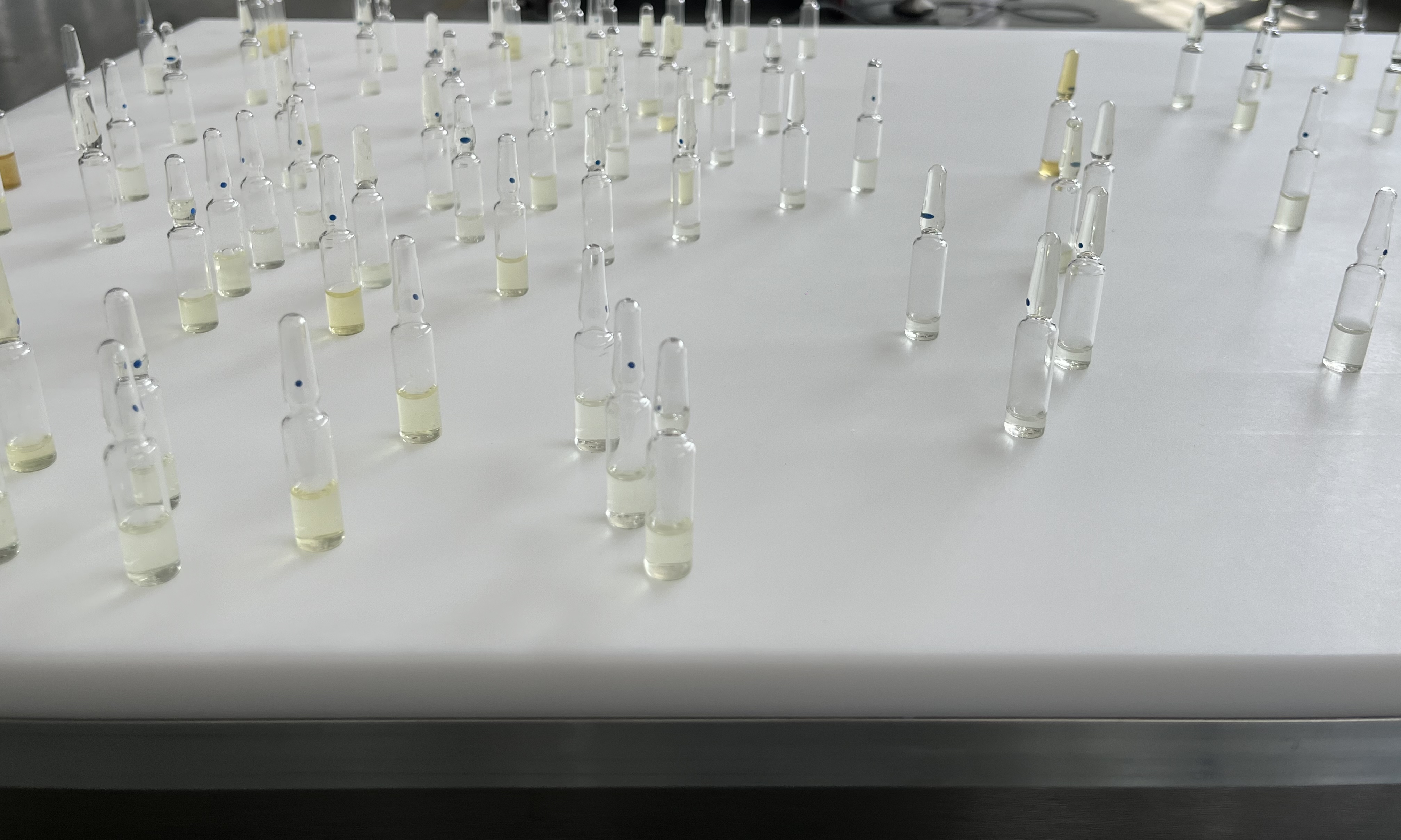

Vibration platforms

Vibration platforms

The gentle and stable platform feeding system has a good conveying effect on plastic bottles,

glass bottles and other lightweight and fragile products, and can be applied to cartoning machines,

labeling machines, capping machines, filling machines and other bottle feeding applications.

Features:

Comply with GMP requirements.

High capacity, low noise.

Lower product wear.

Easy to clean.

Uninterrupted supply of follow-up processes.

Quick and easy, tool-free adjustment.

Wide range of practicality.

Flexible customization.

Conveyors

Incline and filling hoppers

Controler

Controler

GOODBOWL has a self-developed vibration controller, and can also configure the control module of the specified brand for customers.

Spring untangler

Spring untangler

A spring unwinder is typically used for storage with a vibrating conveyor or hopper that feeds the springs to a spring unraveler, which then feeds the separated springs to another vibrating feeder for sorting and processing for further processing.